Surface finish is one essential factor that must be taken into consideration in the production of high-quality glass products. Smooth, glossy and defect-free glass surfaces are the requirement for applications such as automotive, electronics or architecture. Shandong Huamei New Material Technology Co., Ltd. Shandong Huamei New Material Technology Co., Ltd. knows the importance a perfect surface makes in glass manufacturing - let us help you improve or maintain yours! With Silicon Carbide (SiC) heating plates, Huamei is changing the way glass is made and raising the bar for superior surface finish.

Advanced heating for better glass quality

The heating process of production play a significant role in the quality of glass products. Conventional heat sources may cause uneven temperature, and inconsistent heating which results in poor surface finish. But now, with the advent of SiC heating plates from Huamei, glass manufactures finally have access to cutting edge technology for an even heat output that universally heats the mass along with far better temperature control and quality. With SiC heating plates, glass manufacturers are able to raise the bar and cater to increasing market requirements for flawless glass surfaces.

Using SiC heating plate, making glass surface beautiful,and even.

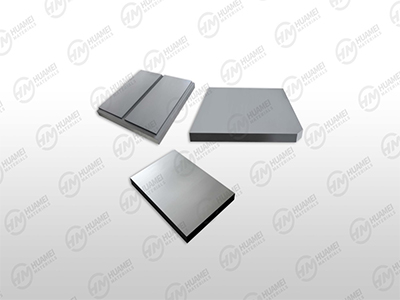

Huamei SiC Heating Elements are cut back to the cold ends, adapted to the glass production thereby achieving a better surface output. Silicon carbide has a high thermal conductivity, resistance to thermal shock, and ability to withstand high temperatures. Used for glass production process, SiC heating plates provides homogeneous and uniform heat transfer, little energy consumption and good surface smoothness. Glassware made by using SiC heating plates are of superior quality and clearness, therefore there is a possibility for better surface finish.

Raising the bar for glass production with SiC heating plates

Huamei SiC heating plates are glass utilities that allow glass makers to achieve unparalleled levels of quality. State-of-the-art SiC heating elements for glass applications Superior technology of SiC Heating Plates provide you better efficiency, productivity and quality control in your production RBSiC/SiSiC components for glass forming processes of glass. By combining the RBSIC/SISIC Ceramics of Huamei and innovative solutions, manufactures are now able to reach new ground in terms of perfect surface finish. SiC heating plates are used in the development of advanced features that help manufacturers to be more competitive, represent a reference in quality and attend to increasingly demanding customers looking for high-quality glass.

The effects of SiC on heating plates

The SiC heating plates for the glass industry is of great influence. By integrating this advanced technology, the glass manufacturer can benefit from increased efficiency in its processes and lower production cost higher quality products. "Installation of the SiC heating plates in conventional manufacturing systems is a direct, no-hassle move to advanced Silicon carbide (SiC) heating plates for glass forming and proven heating technology." This means the glass industry can satisfy growing customer demand for perfect surface quality and achieve a significant competitive advantage. Huamei has brought about more than a technical development with its SiC heating elements, it is changing the glass industry in terms of surface property and innovation!